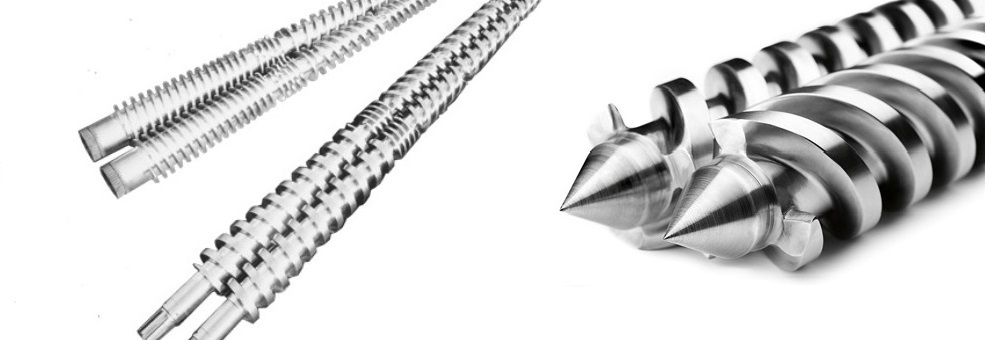

Bi Metalic Screw Barrel

Through the quenching and permeability nitrogen treatment , the hardness of screw can research HRC60°-65° ,which with characteristic of high hard wearing, hard corrosion. It is suitable for processing of XPS, film, blowing machine, PE aluminum-plastic plate, chemical fiber equipment, EPE foaming material , Granulation of waste plastics, PE pipe, WPC, etc.The service life of five or eight times longer than the nitrided screw.Wc-10 tungsten carbide alloy , with the characteristic of high hardness ,high hard-wearing, corrosion resistance , and high- temperature resistance ,the hardness of alloy layer reaches HRC60-65, thus having the service life of two or three times longer than the nitrided barrel. It is suitable for the PVC, PE plus high-calcium powder ,as well as engineering plastics.

The first method of processing screw Taking the steel as base material ,and spraying the Ni-20 at the surface of screw arris ,which with the hardness of HRC58-62. The thickness of alloy surface on the screw arris is the standard value of 1.5-3.5mm, which is the alloy of alkaline resistance and corrosion resistance. It is mainly used in the processing of nylon plus 10%-20% fiberglass, PVC, PC ,and high strength engineering plastics.The service life of three or five times longer than the nitrided screw.

The second method of processing screw Taking the SKD61 or SKD11 as base material .Moreover , the material of 30CrMoVg、34CrAINi7、X35CrMo17、X22CrNi17 can also used into processing .